The European and American construction markets have a growing demand for architectural decorative mesh that combines aesthetics, functionality, and durability. From façades and interior partitions to ceilings, staircases, and balustrades, decorative metal mesh enhances both visual appeal and structural safety. For Chinese manufacturers, offering customized decorative mesh solutions is a key strategy to meet these market requirements and build long-term partnerships with distributors, contractors, and architects overseas.

This article explores effective strategies for providing tailored decorative mesh solutions for the European and American construction industry, including design customization, material selection, quality assurance, and technical support.

1. Understand Client Needs and Project Requirements

The first step in providing a customized solution is understanding the specific needs of clients:

Project type: Commercial, residential, public, or industrial

Application: Façade cladding, interior partitions, stair railings, ceilings, or decorative panels

Design requirements: Patterns, transparency, perforation, or architectural style

Safety and compliance: Fire ratings, structural strength, and local building codes

Engaging with architects and contractors early allows manufacturers to provide solutions that balance aesthetics, functionality, and cost-effectiveness.

2. Offer Material and Finish Options

Different projects and environments require different materials and finishes:

Stainless steel mesh: Corrosion-resistant, ideal for outdoor façades and wet environments

Aluminum mesh: Lightweight and suitable for interior decorative elements

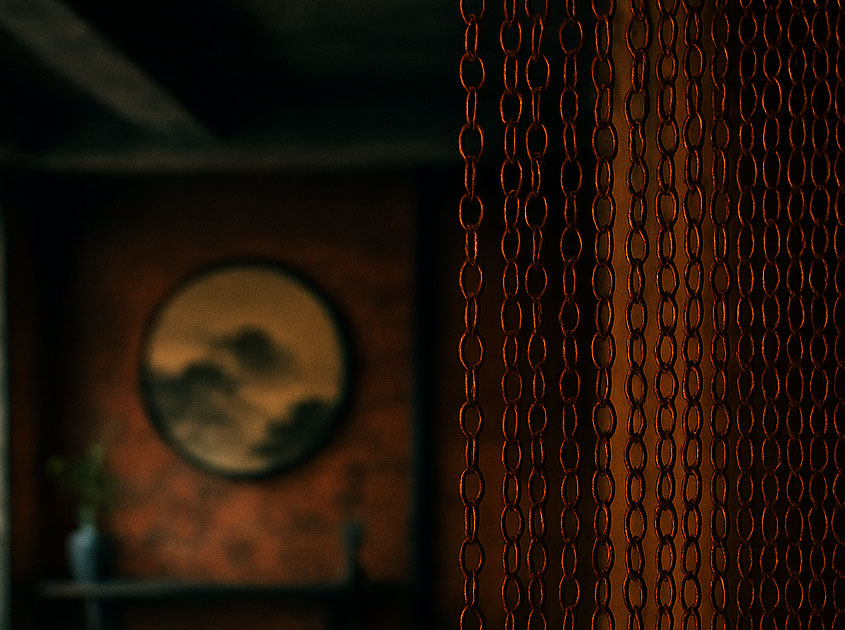

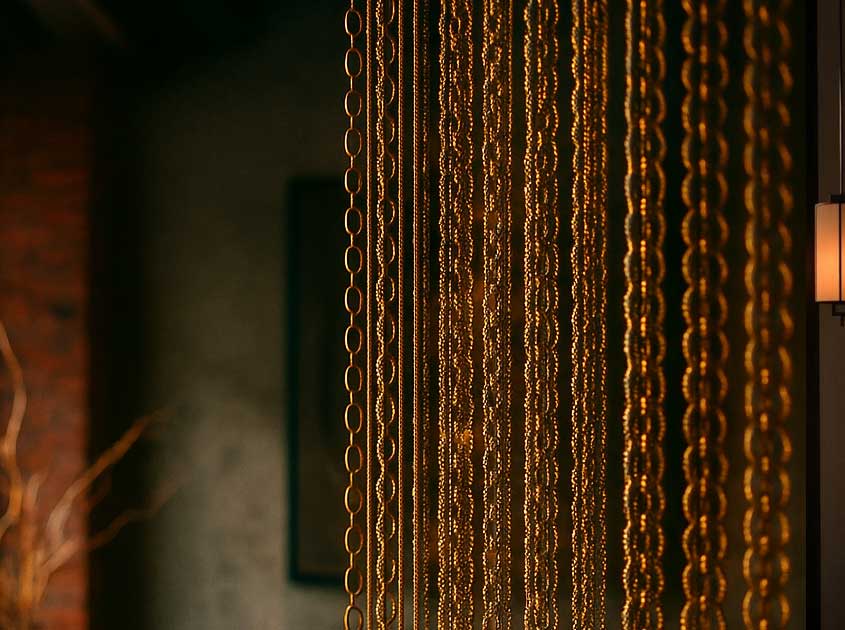

Copper, bronze, or brass mesh: Adds luxury appeal and distinctive architectural style

Powder-coated or painted finishes: Enhances color variety and durability

Providing a wide range of material and finish options allows European and American clients to achieve their desired visual effect while maintaining performance standards.

3. Design and Pattern Customization

Custom patterns and designs distinguish projects in the competitive construction market:

CNC cutting or laser-cut perforation for unique geometric or artistic patterns

Varying mesh aperture and wire diameter for visual or functional effects

Integration with other materials such as glass, wood, or stone

Decorative finishes that align with the project’s architectural style

Chinese manufacturers with advanced machinery and design capabilities can translate client visions into functional mesh products.

4. Ensure Compliance with Local Standards

European and American construction projects often require strict compliance with building codes:

Structural strength and load-bearing capacity: Verified through tensile and impact tests

Fire safety standards: EN 13501 (Europe) or ASTM E84 (USA) for flammability

Corrosion resistance: Salt spray or humidity testing for outdoor applications

Environmental compliance: REACH certification for Europe, RoHS compliance for the US

Manufacturers providing certified products increase client confidence and market competitiveness.

5. Provide Technical Support and Installation Guidance

Customization requires detailed technical support:

Installation manuals and guidelines

Load calculations for façades, partitions, and balustrades

Recommendations for fixings, frames, and edge treatments

On-site or virtual technical consultation

Proper technical support ensures that custom decorative mesh is installed correctly, avoiding safety issues and maintaining aesthetic quality.

6. Offer Prototyping and Sample Production

Before mass production, offering samples or prototypes helps clients evaluate:

Mesh pattern, transparency, and visual effects

Material texture and coating quality

Structural performance for specific applications

Samples allow for early adjustments, reducing errors, improving client satisfaction, and streamlining production.

7. Ensure Efficient Logistics and Delivery

European and American construction projects often require timely delivery:

Use sea, air, or combined logistics depending on urgency and shipment volume

Protective packaging to avoid scratches, deformation, and corrosion

Clear labeling and documentation for customs clearance

Reliable delivery ensures that customized decorative mesh arrives on schedule and in perfect condition.

8. Collaborate Closely with Designers and Contractors

Long-term success depends on strong collaboration:

Participate in project planning and design discussions

Offer advice on mesh specifications and customization options

Provide continuous updates and solutions during production

Support post-installation adjustments if required

Close collaboration strengthens trust, project success, and repeat business.

Conclusion

Providing customized decorative mesh solutions for the European and American construction industry requires a deep understanding of client requirements, material selection, design capabilities, compliance with standards, and technical support. Chinese manufacturers who offer flexible design, certified quality, prototyping, and reliable logistics can effectively serve architects, contractors, and distributors overseas.

By combining creativity, technical expertise, and quality assurance, manufacturers can deliver decorative mesh solutions that meet the functional, aesthetic, and regulatory demands of international construction projects, helping clients create standout architectural designs while ensuring durability and safety.

next:How Middle Eastern Countries Can Choose the Right Decorative Mesh Products

© 2025 Joinwin Architectural Wire. All Rights Reserved. | Sitemap

Recommended Read

How Middle Eastern Countries Can Choose the Right Decorative Mesh Products

How Middle East Distributors Can Ensure Quality and On-Time Delivery of Decorative Mesh Products from China

Architectural metal mesh shows its unique value in many fields